Automated condition assessment of

CN RAIL BRIDGES

CN Rail | Pemberton, Clinton and Blue River, BC

The three rail bridges located throughout the interior of British Columbia in are owned and managed by CN Rail. These are critical structures located in Pemberton, Clinton and Blue River, BC

Project Overview

Due to inaccessibilty and lack of proper clearance under these bridges, it has been difficult to survey these assets manually. Traditional inspection methods were not adequate due to these limitations.

The three rail bridges owned by CN Rail, namely:

- Pemberton Bridge

- Clinton Bridge

- Blue River Bridge

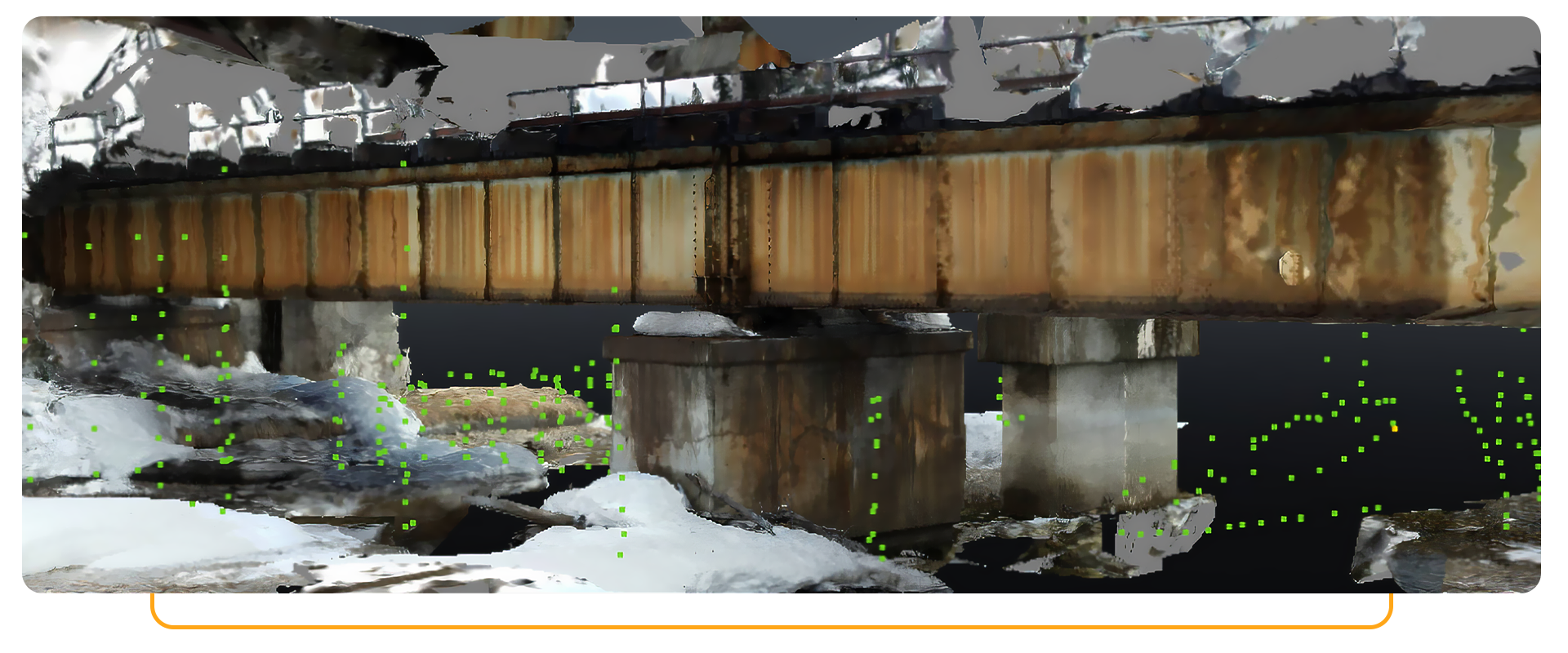

CN Rail worked with Niricson for improved data collection and collected a total of 3 types of surface and subsurface defects. To facilitate a comprehensive examination, the Pemberton site was subdivided into five distinct components: East Abutment, West Abutment, Underside of Bridge, North Façade of Bridge Deck, and South Façade of Bridge Deck. The Clinton site was partitioned into two sections, namely the South Abutment and the North Abutment, and the Blue River site was subdivided into three distinct components: Middle Pier, North Abutment, and South Abutment.

The Solution

Niricson, in collaboration with CN Rail, conducted an automated inspection of all three bridges. By employing DRONIC™ (patented multi-layered data collection and fusion architecture, along with a proprietary drone-equipped concrete sounding hammer), AUTOSPEX™ (patent pending AI-backed platform for defect detection, quantification, and tracking for digital infrastructure condition survey) technologies, and a patented drone-equipped concrete sounding hammer NCX and an AI-backed defect detection platform, collected optical imagery and acoustic sound data, they were able to perform a detailed and efficient assessment reducing the risk of missing critical defects.

The team mapped defects like cracking, spalling and delamination on the bridge’s key components, providing efficient and detailed coverage. Niricson’s UAV-sounding mechanism enhanced drafting efficiency, reduced documentation time, and eliminated condition uncertainties, mitigating asset risk.

- Access hard-to-reach areas for precise assessments.

- Reduced carbon emissions and waste.

- Efficient coverage saves time and labor.

Bridge Health not only ensures the safety and longevity of bridges but also supports local economies by maintaining uninterrupted trade and tourism flow. These technologies herald a new era in infrastructure management, promising both immediate and long-term benefits.