DRONIC™

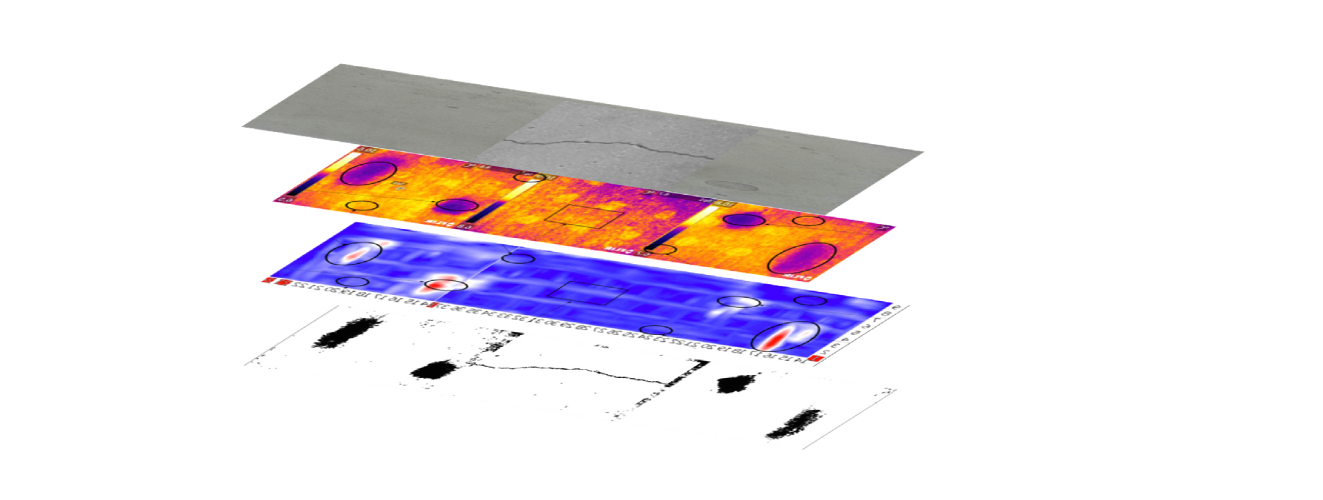

Patented multi-layered data collection and fusion architecture

To keep assets safe, civil and structural engineers complete detailed condition assessments and inspections of large civil infrastructure, often mapping and quantifying visual cracks and spalls and non-visual drummy-concrete on as-built drawings or sketches with manual notes and photos.

While valuable for fulfilling regulatory requirements and identifying specific defects, challenges with the current methodology include challenges accessing complex structures, subjective inspection results, and difficulties identifying and quantifying changes in a structure’s condition between two different inspections/assessments.

In addition to these three primary datasets, DRONIC™ also collects positional information, camera angles, drone speeds, acquisition distances, altitude, etc.

To correlate the defects not only to the global positioning system but also to local x-y coordinates. This additional information is stored to inspect structures on a periodic basis to detect and quantify a small change in the defects over time.

The sensors use an accelerometer and a high-sensitivity microphone to identify the potential presence of delamination in concrete structures up to a depth of 8 inches. It captures the accelerometer and microphone readings and uses machine learning and an onboard GNSS and PPK technology to correctly identify delamination and determine the precise location of each data collection point. Data is stored locally on the system and after each collection, signal processing and positioning data are combined to produce georeferenced delamination maps.

NDX

Niricson’s acoustic sensor is the first ever UAV-mounted concrete-sounding sensor Intended for flat surfaces and angles of up to 45 degrees. The acoustic-sounding payload doesn’t require manned access to the civil assets.

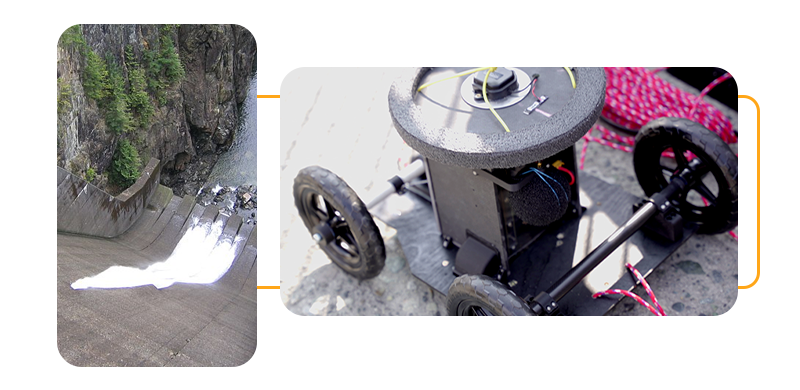

We have used our patented NDX technology for a lot of different projects, e.g.:

- spillways of the Duncairn and LaFleche dams in Saskatchewan.

NCX

A UAV-mounted concrete-sounding sensor intended for angles between 80 degrees and 180 degrees. This payload can work on vertical walls and ceilings doesn’t require manned access to the civil assets and can reach hard-to-access regions of the asset, which are otherwise difficult or unsafe to test.

Here are some of the recent projects where we used our patented NCX technology:

- Cataract Dam in Cataract, Australia

- San Remo Bridge in Newhaven, Australia

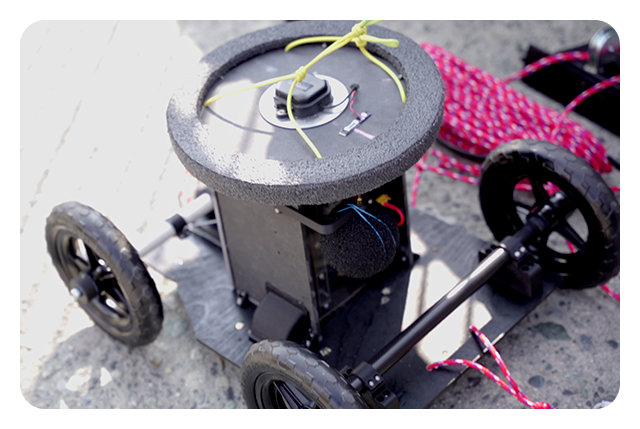

NDX-CART

A remotely operatable cart-mounted concrete-sounding sensor intended for angles between 45 degrees and 80 degrees. Depending on the structure and access limitations, this one can access hard-to-access locations that are otherwise difficult or unsafe to reach with rope access methods.

We have used our patented NDX-Cart technology for a few different projects, including:

- Cleveland Dam in Vancouver

- Spillway of the Horse Mesa Dam dam in Phoenix, Arizona.

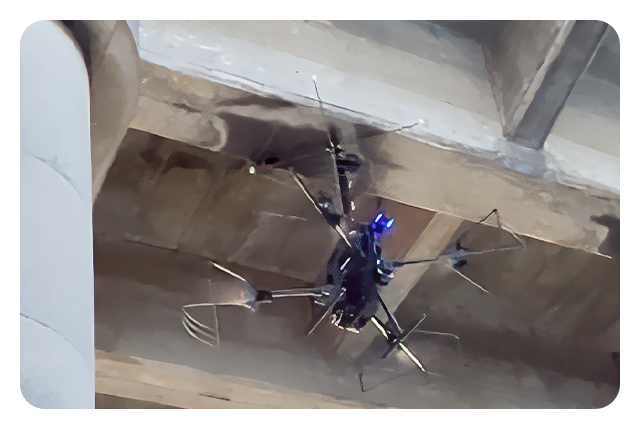

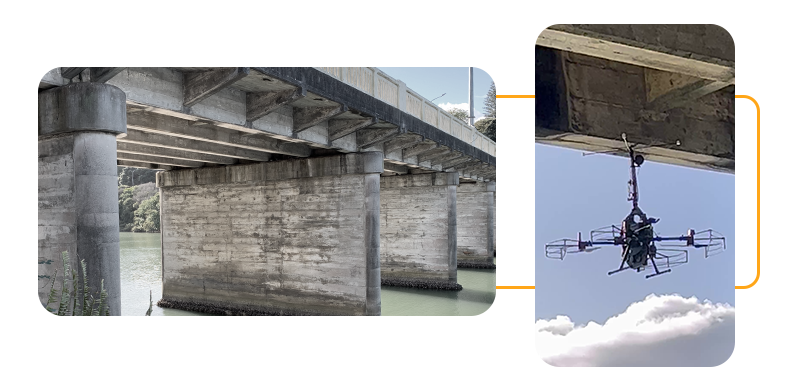

INVERTED – NCX

A UAV-mounted concrete-sounding sensor intended for angles at 180 degrees. This payload can work on sections under the bridge and ceilings. It doesn’t require manned access to the civil assets and is able to reach hard to access regions of the asset.

We recently used our patented technology during our inspection at the Purewa Bridge, Auckland, New Zealand.

The concrete-sounding devices strike at precise and repeatable velocities. Several strikes are made at each sample location to ensure reliable results.

They use an individually calibrated high-dynamic range microphone with a high resolution and high sample rate recording system to collect the concrete response from the strike.

Acoustics data is collected and processed for the Spillway section. Niricson’s proprietary NCX and NDX used the striking mechanism which replicates the industry standard hammer test. The classification of whether the concrete is delaminated or not is based on specific signal characteristics of the audio collected. The soundness of the concrete was determined by Niricson’s engineering team using a frequency spectrum and also it leverages machine learning techniques and relies on training datasets composed of real-world delaminated and non-delaminated signals.

Opposed to a subjective individual inspector, these responses are analyzed using machine learning techniques based on a database of delamination and solid concrete responses from many structures. This means that Niricson’s delamination maps have increased objectivity, allowing the baseline dataset to remain a baseline, with each subsequent year of data collection able to be directly compared to the previous.

Experience the future of Asset Management

Get in touch with us and our team of experts will walk you through our platform and show you how the World’s Leading Infrastructure Condition Assessment Platform is using Artificial Intelligence (AI) and Machine Learning to make infrastructure safer.