Stop Dam Damage in Its Tracks: The Automated Condition Survey for Lasting Repairs

Dams are essential for flood control, hydroelectric generation, and water storage, making their safety a top priority. Niricson’s AI-backed defect detection platform, AUTOSPEX®, paired with DRONIC®—a patented multi-layered data collection and fusion architecture—delivers automated condition surveys that identify and track defects such as cracks, spalls, and delamination.

By comparing survey data over time, like the failed crack sealant detected between 2020 and 2023, asset owners can establish a digital baseline, validate repairs, and make proactive, data-driven decisions to ensure the long-term integrity of their infrastructure.

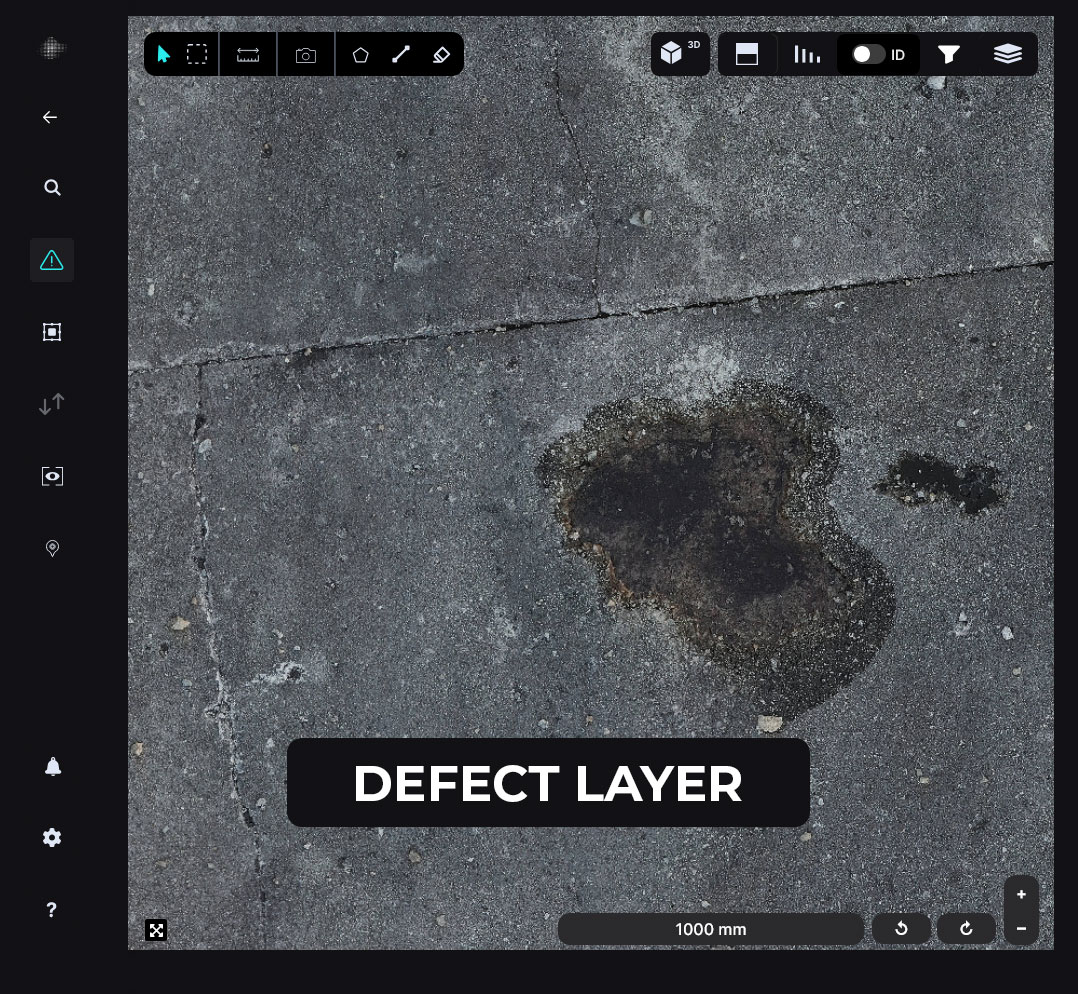

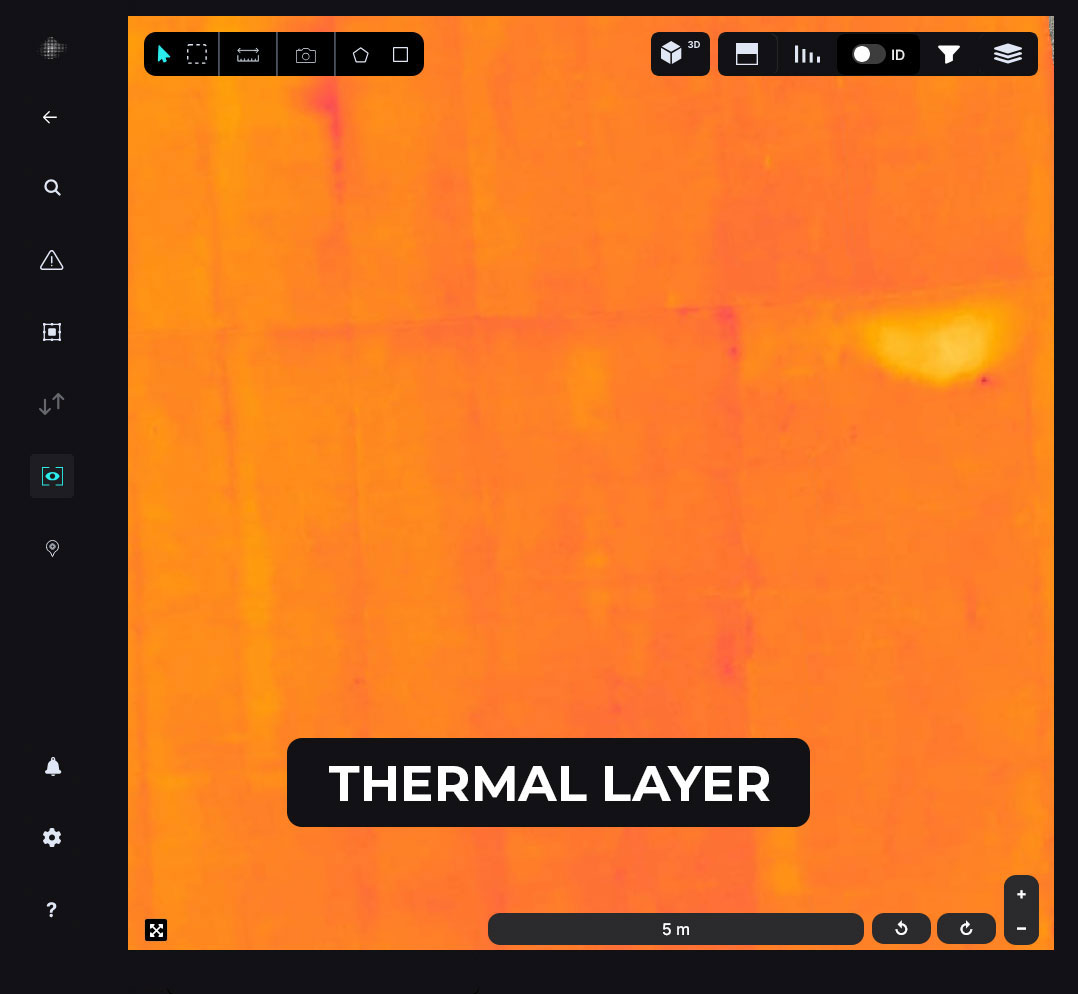

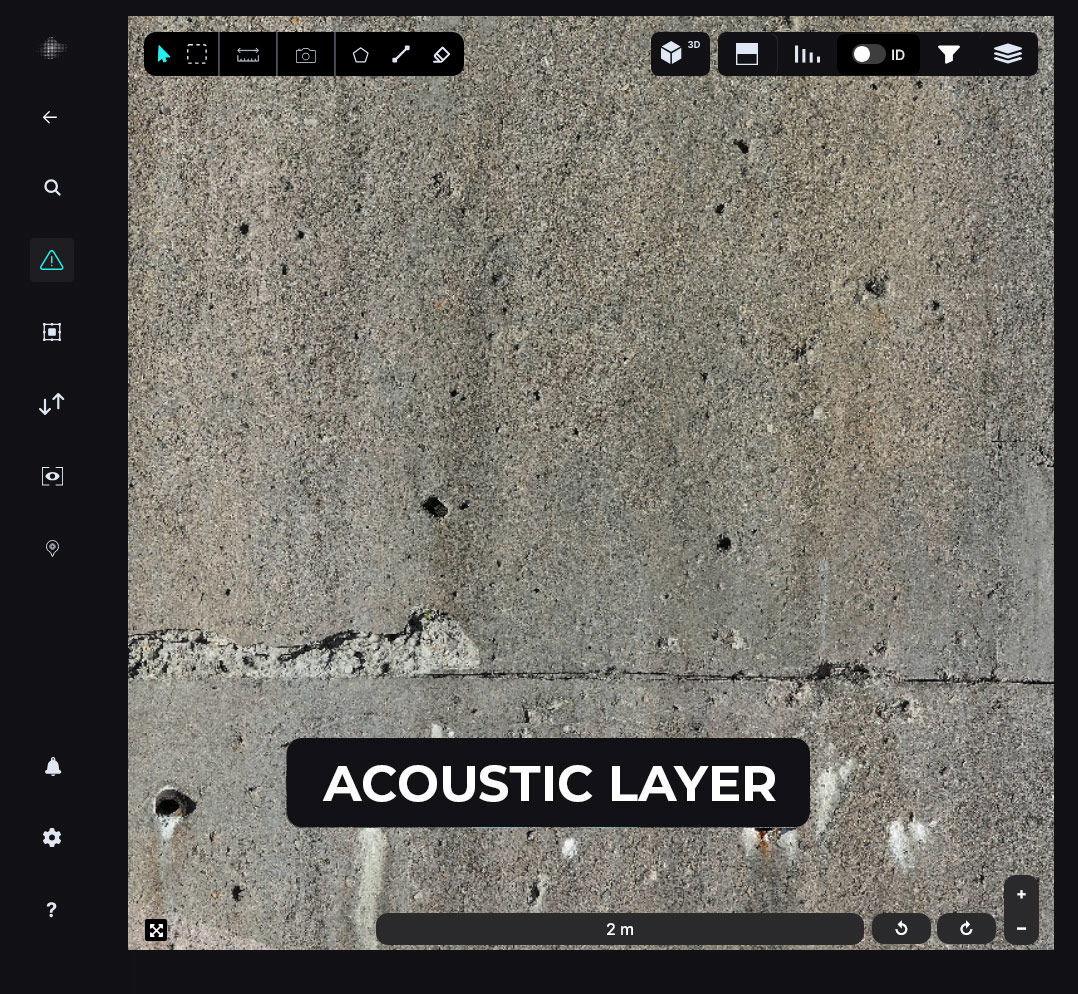

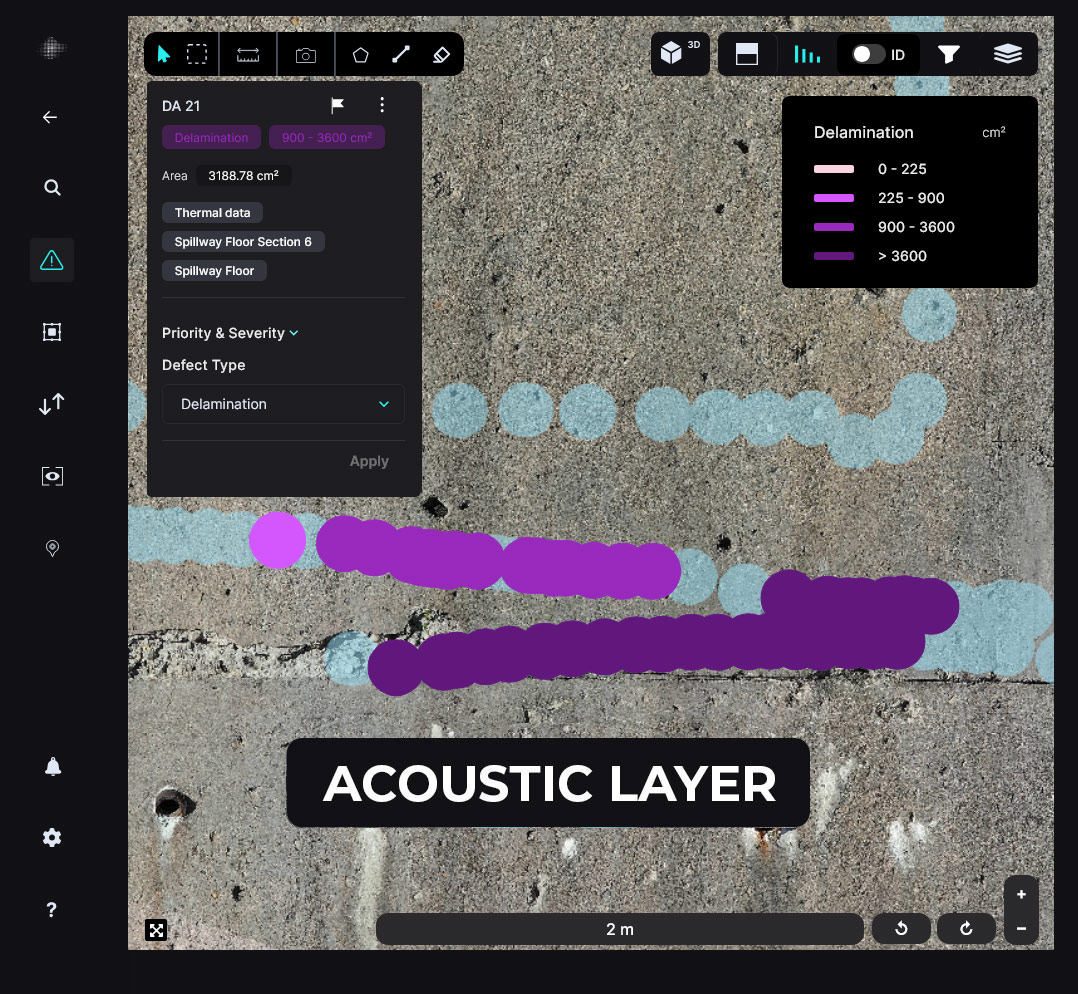

AUTOSPEX uses optical imagery to identify surficial defects on the concrete dam or spillway. We also use commercial-off-the-shelf thermal cameras to identify and map voids and delamination up to 50mm into the concrete. Our proprietary acoustic sensor can detect and create a geo-referenced map of delamination.

We Empower Asset Management Through Change Detection

Our cloud platform, AUTOSPEX, uses extensive surveys to deliver advanced change detection and data comparison for dams and spillways. By tracking defect variations over time, we enable you to construct reliable models for asset deterioration. This comprehensive approach empowers you to identify trends, predict future issues, and make informed decisions for long-term maintenance and safety.

We Provide Visualization for In-Depth Asset Insights

We offer our clients a thorough visualization on AUTOSPEX, detailing the results of each condition survey. This comprehensive documentation provides an in-depth overview of the current state of their dam or spillway, highlighting key findings and any areas of concern. With this detailed information, they can take targeted action to maintain the safety and integrity of their assets.

We Create High-Resolution 3D Models for Asset Monitoring

Using advanced photogrammetry, we produce high-resolution 3D models of Dams and Spillways, offering a clear and detailed view of asset conditions. These digital twins help teams track changes over time, make informed decisions, and optimize asset management.

Our Innovative Technology is Safer for Operations

By using advanced robotics, drones, and patented technology, our process for dams and spillways is safer. This innovative approach reduces the need for heavy equipment, rope access, scaffolding, and excessive labor, leading to a safer work environment and more efficient operations.

We Help Optimize Maintenance with Precise Planning

Our solution helps clients to quickly determine the amount of repair work required for any specific defect in their dam and spillway maintenance. With precise quantification, they can plan projects more efficiently, reduce waste, and ensure they have the right resources on hand to complete repairs on time and within budget.

Case Studies

Check out the success stories of industry-leading professionals who put their trust in Niricson for a better condition survey of their assets to make infrastructure safer.

Experience the future of Asset Management

Get in touch with us and our team of experts will walk you through our platform and show you how we use automated condition assessment to make infrastructure safer.