Transportation

Bridges

Bridges connect our communities, serving as vital economic and communal arteries, helping deliver goods and services, and connect people to their communities. Proper bridge condition is critical for public safety, as well as for reducing congestion and creating efficient traffic routes.

However, traditional bridge inspections and condition assessments are difficult. Many detailed inspections involve snooper trucks, rope access, or scaffolding, and often result in a laborious and subjective condition assessment that puts personnel at risk. Furthermore, depending on the size of the structure and level of inspection detail, structural engineers only inspect a portion of structure, and extrapolate the data to the entire structure. In fact, a FHWA report concluded that visual inspections conducted using traditional methods often miss defects and often vary depending on the inspector and their experience.

The AUTOSPEX™ and DRONIC™ solution developed by NIRICSON™ eliminates the need for heavy equipment like scaffolding and cranes, eliminates subjectivity, and allows engineers to objectively monitor defects across their entire structure. With AUTOSPEX™ and the NIRICSON™ drone-based concrete sounding hammer, engineers receive the highest quality deterioration information for preventive maintenance, capital planning, and asset management.

Data Processing

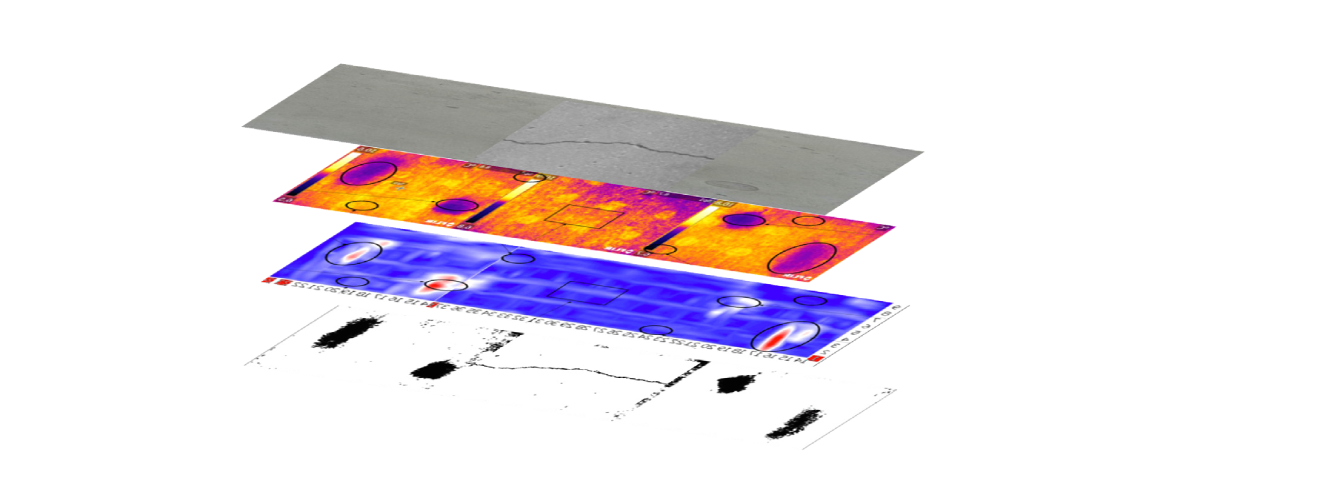

NIRICSONᵀᴹ processes optical, thermal, and acoustic data collected by our third-party Unmanned Aerial Vehicle (UAV) service providers. This data is used to build an interactive baseline condition map for the entire structure.

Optical Imaging

On concrete airstrips, NIRICSONᵀᴹ uses optical imagery to identify surficial defects. Our subcontractors collect images with a Ground Sampling Distance (GSD) of 1 mm. This imagery is processed into a 3D model, and the NIRICSON™ AI algorithm automatically maps and quantifies each defect.

Infrared Imaging

NIRICSONᵀᴹ uses commercial-off-the-shelf thermal cameras to identify and map voids and delamination up to 50mm into the concrete.

Acoustic Signatures

NIRICSONᵀᴹ developed a proprietary acoustic sensor that can detect and create a geo-referenced map of delamination. This UAV-equipped sensor replaces the well-known ‘hammer sounding test’. The sensor makes physical contact with the surface of the structure and sends a stress wave into the concrete, which is then recorded to detect delamination up to 200mm into the concrete.

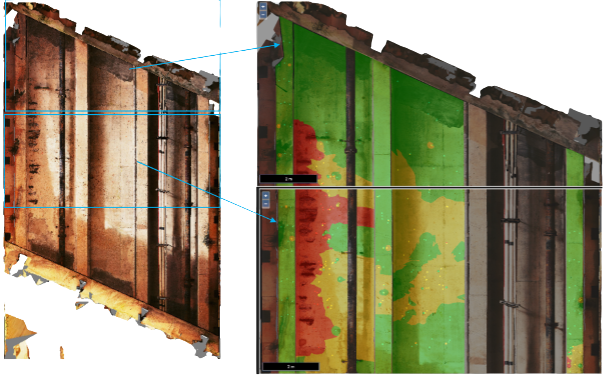

AUTOSPEX™

Bridge

With AUTOSPEXᵀᴹ, asset owners can easily navigate their structure, interact with the automatically detected defects, and quantify the cracks, spalls, leakage, and delamination on the concrete. With automated defect change-detection built in to AUTOSPEXᵀᴹ, multiple surveys allow asset owners to quantifiably monitor their structure over time, conduct detailed structural analyses, calculate section loss and bridge load ratings, and design accurate maintenance plans for asset repair and rehabilitation.

What to Expect...

- 3D Model

- Defect Map

- Report Detailing Methodologies

Benefits

NIRICSONᵀᴹ offers a complete and reliable solution for asset owners. AUTOSPEXᵀᴹ allows users to visualize and overlay defects discovered by optical, thermal, and acoustic analyses, providing a baseline assessment of the structure, which can be tracked over time.

Traffic Control

Data collection method allows for traffic to flow as usual

Change Detection

Track defect changes over time to build reliable asset deterioration models

Enhanced Maintenance Planning

Easily quantify the amout of material needed for repairs

Unprecedented Documentation

Detailed documentation of bridge condition

Simpler & Safer

Reduce the need for heavy equipment & labour

Why Choose Niricson?

NIRICSON offers a complete and reliable solution for asset owners. AUTOSPEXᵀᴹ allows users to visualize and overlay defects discovered by optical, thermal, and acoustic analyses, providing a baseline assessment of the structure, which can be tracked over time.

Niricson's Method | Traditional Method | |

Repeatable Through Time |  |  |

Reduced Operational Liability |  |  |

Time-Efficient |  |  |

Reduces risk of asset failure |  |  |

Identifies and Quantifies Defects |  |  |

100% Coverage of Asset |  |  |

Predictive Capabilities and Deterioration Modeling |  |  |

3D Visualization of Data |  |  |

Allows for Better Allocation of Maintenance, Rehab, Replacement and Deterioration Modeling/Asset Lifecycle Planning |  |  |

Experience the future of Asset Management

Get in touch with us and our team of experts will walk you through our platform and show you how the World’s Leading Infrastructure Condition Assessment Platform is using Artificial Intelligence (AI) and Machine Learning to make infrastructure safer.