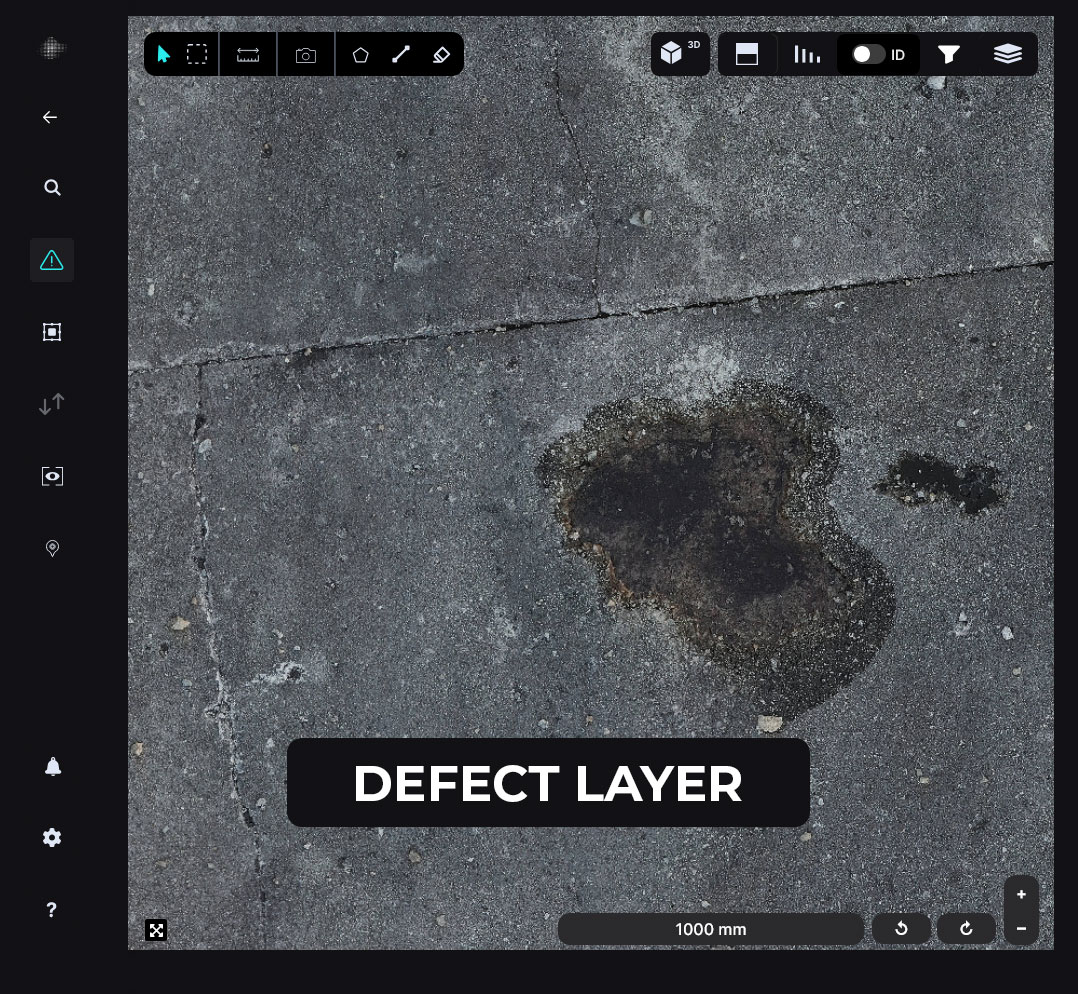

AUTOSPEX uses optical imagery to identify surficial defects on the concrete and asphalt surface of runways. By creating a digital baseline for airfield pavement, asset owners receive the most objective and quantifiable asset deterioration information for proactive and preventive maintenance, helping to eliminate pavement-related damage to aircraft and operational disruptions due to pavement maintenance and construction.

- Ability to leverage data to make estimates on the amount of material (linear feet of sealant)

- Obtain inputs for PCI Calculations

- More accurate and complete deterioration data for deterioration modelling for asset management

- Improved documentation and year-to-year referencing

We provide repeatable deterioration modelling for Airfield Maintenance

By performing multiple inspections, AUTOSPEX can utilize the data to provide advanced change detection and data comparison for runways. By tracking defect variations over time, we enable you to construct reliable models for asset deterioration. This comprehensive approach empowers you to identify trends, predict future issues, and make informed decisions for long-term maintenance and safety.

Our solution eliminates incompleteness and subjectivity

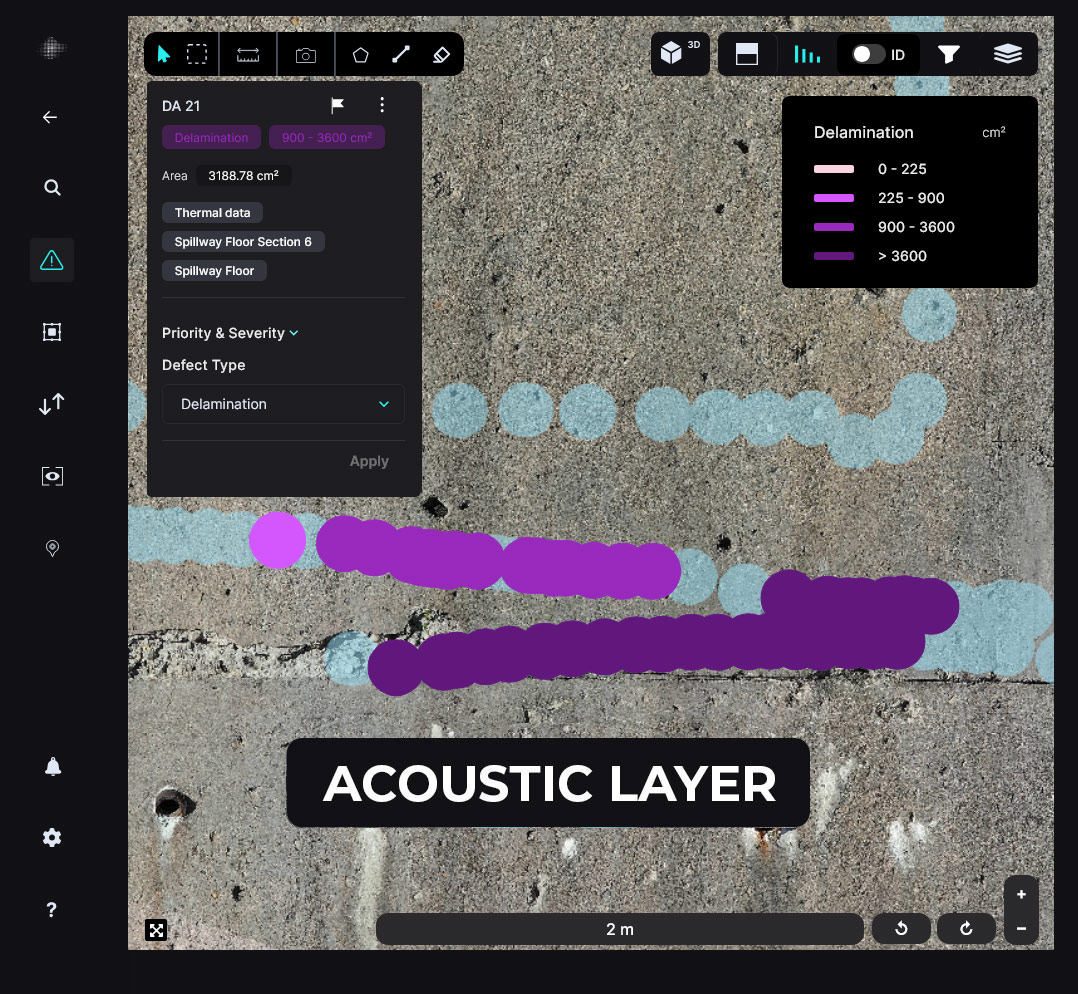

Using machine learning and AI, AUTOSPEX maps and quantifies pavement distresses, establishing a thorough digital baseline. This digital baseline delivers objective and precise data on asset deterioration, empowering asset owners to undertake proactive and preventive maintenance. Consequently, it reduces the risk of pavement-related aircraft damage and minimizes operational disruptions caused by pavement maintenance and construction.

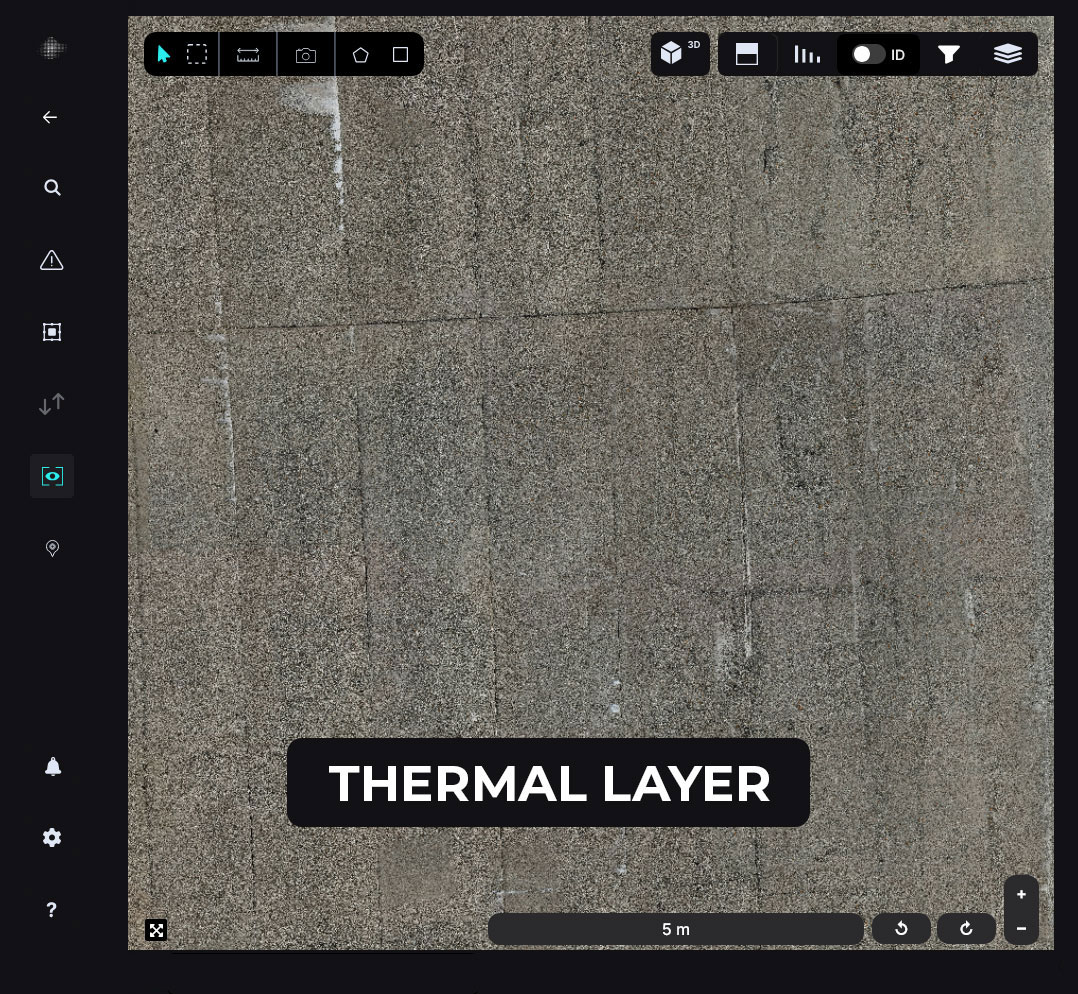

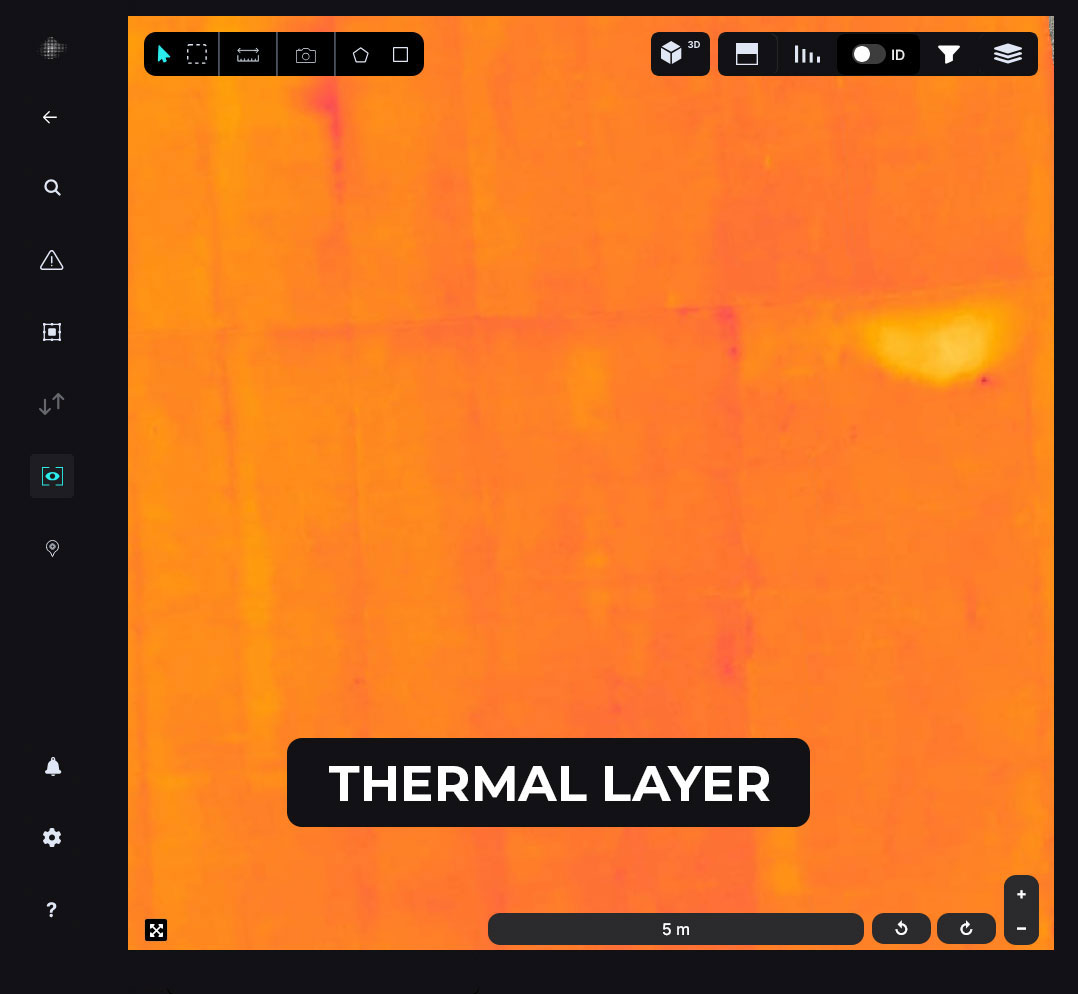

We ensure detailed coverage of the entire runway

Through our comprehensive approach to airfield maintenance, we model pavement deterioration accurately and efficiently. By leveraging AI and machine learning, AUTOSPEX precisely maps and quantifies all pavement distresses across the entire airfield. Our solution eliminates subjective assessments and data gaps, ensuring you have detailed, quantifiable insights into the entire airfield’s deterioration.

We help reduce operational downtime for airfield inspection

Utilizing autonomous UAV flights, we conduct comprehensive data collection scans within just one hour. This streamlined approach ensures minimal disruption to operations while delivering detailed and accurate inspection data. By leveraging autonomous UAV technology, we enable efficient and timely airfield assessments, allowing for proactive maintenance planning and enhanced operational continuity.

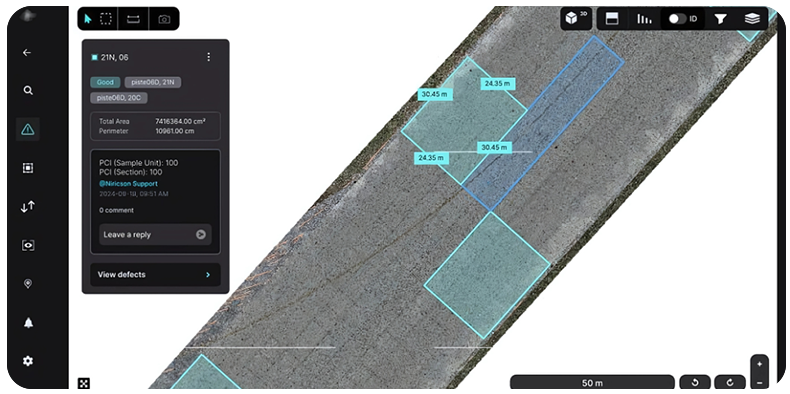

We deliver accurate PCI calculations with comprehensive surface coverage

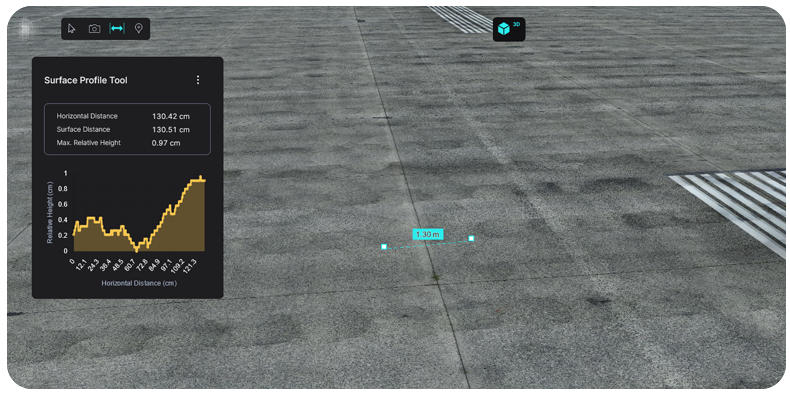

Our photogrammetry-based methodology ensures precise Pavement Condition Index (PCI) calculations, closely matching the results of traditional inspections. By achieving the smallest delta compared to conventional methods, we provide asset owners with confidence in receiving accurate and reliable assessments.

With a ground sampling distance (GSD) of 1mm or better, we accurately detect and map raveling, weathering, and other critical pavement distresses. This approach combines traditional accuracy with modern, data-driven efficiency.

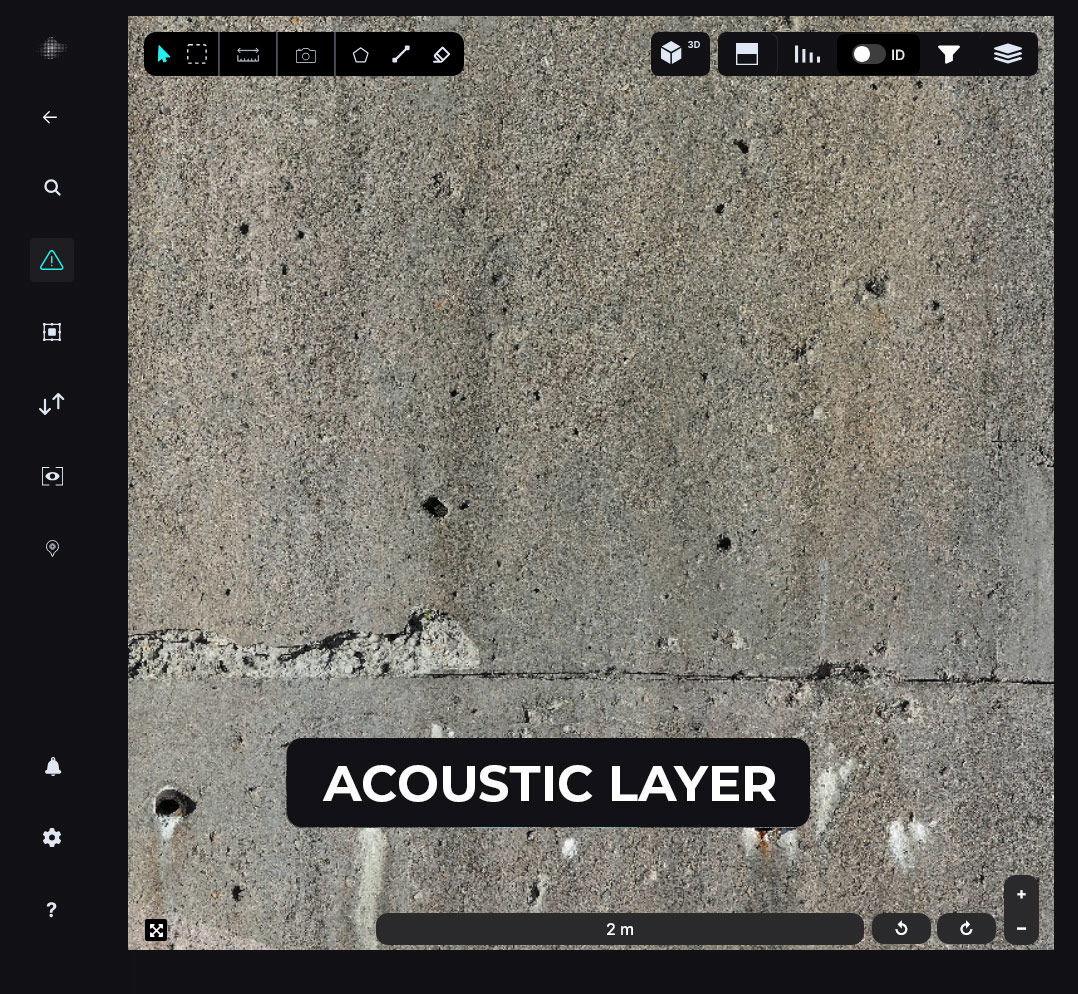

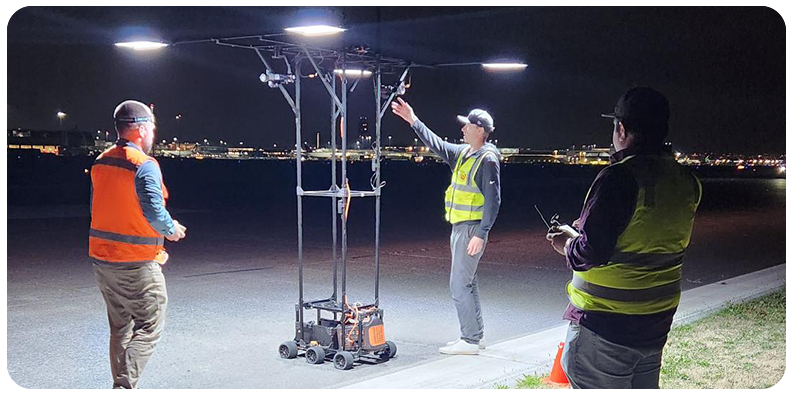

Meet Rover – Taking the Next Step in Airfield Optical and Delamination Data Collection

Our engineering team have developed a ROVER platform to tackle photogrammetry missions at airfields:

- ROVER collects imagery both day and night, enabling surveys to be conducted during off-peak airfield hours, reducing costly airport shutdowns for inspections.

- Equipped with an onboard hammer-tapper, ROVER collects both imagery and delamination data, automating delamination surveys for concrete slab aprons, taxiways, and runways.

- ROVER allows asset owners to complete PCI surveys faster and more efficiently while gathering more detailed data for maintenance planning.

Airfield Case Study

Check out the success stories of industry-leading professionals who put their trust in Niricson for a better condition survey of their assets to make infrastructure safer.

Experience the future of Asset Management

Get in touch with us and our team of experts will walk you through our platform and show you how the World’s Leading Infrastructure Condition Assessment Platform is using Artificial Intelligence (AI) and Machine Learning to make infrastructure safer.